Pepper drying machines are increasingly being installed in African countries to improve post-harvest processing, reduce losses, and increase the value of pepper crops. These machines are particularly useful for farmers and agribusinesses involved in the production of chili peppers, bell peppers, and other varieties.

Key Benefits of Pepper Drying Machines:

01

Straight Teet

They provide faster and more consistent drying compared to traditional sun-drying methods.

02

Quality Preservation

Controlled drying preserves the color, flavor, and nutritional content of peppers.

03

Reduced Losses

Minimizes losses due to spoilage, pests, and unpredictable weather.

04

Scalability

Machines can process large quantities, making them suitable for both small-scale and commercial operations.

05

Marketability

Dried peppers fetch higher prices in local and international markets.

Common Types of Pepper Drying Machines:

- Solar Dryers: Use solar energy, cost-effective, and eco-friendly.

- Electric/Mechanical Dryers: Powered by electricity or generators, offering faster drying.

- Hybrid Dryers: Combine solar and mechanical methods for better efficiency.

Notable Installations:

West Africa

Countries like Ghana and Nigeria are investing in pepper drying machines to boost exports.

East Africa

Kenya and Tanzania are adopting these technologies for smallholder farmers.

Southern Africa

South Africa uses advanced drying systems for commercial pepper processing.

Would you like details on suppliers, installation processes, or examples of specific projects in Africa?

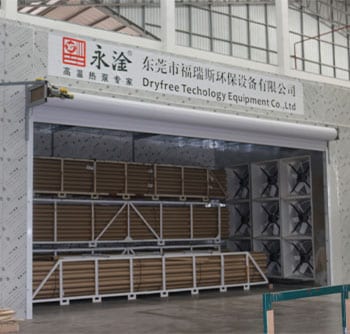

| Chili type: | Round Chili |

| Moisture: | 85%-10% |

| Heat source: | propane |

| Heat source system: | propane heat exchange furnace (patented product) |

| Drying temperature: | 75 ℃ |

| Capacity: | 8000kg / day |

| Purchase model: | DF -24HP |

| Advantages: | 304 stainless steel mesh belt, air volume and heat energy combined with dry materials, high efficiency and energy saving, drying temperature and speed of dryer can be adjusted, high quality dried product. |